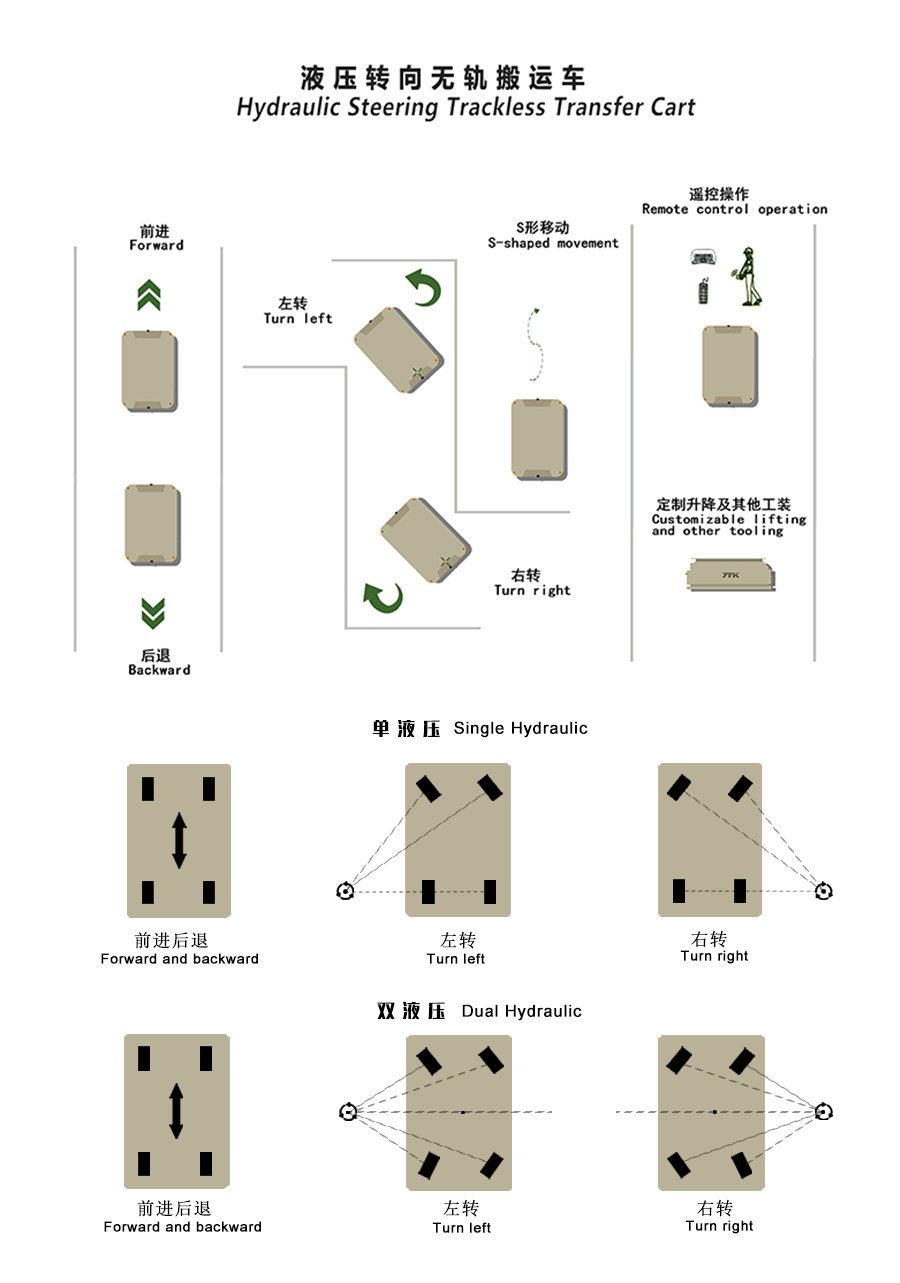

In the design of the 80 Tons Battery Mold Trackless Transport Platform, it is transformed into a balance of "force and skill". This equipment, specially designed for the transportation of giant molds, has completely overturned the steering logic of heavy-duty equipment with its dual hydraulic steering system. It adopts independent hydraulic control for the front and rear wheels When a small radius turn is required, the front and rear wheels deflect in the opposite direction, greatly reducing the turning distance; When driving in a straight line, the two wheels are synchronized and kept parallel to ensure driving stability under a heavy load of 80 tons.

The high torque drive motor, combined with the gearbox, provides continuous and stable traction for the vehicle; The battery pack uses high-capacity energy storage batteries, which can meet 8 hours of continuous operation on a single charge, and supports fast charging mode to reduce downtime waiting time. This combination of "strong power+long endurance" ensures that the equipment remains efficient during high-frequency transportation.

The safety of heavy-duty transport trolley is hidden in every detail design:

-The sound and light alarm system synchronously sends out warnings when the vehicle starts and turns, reminding surrounding personnel to avoid;

-Laser obstacle avoidance sensors are installed around the vehicle, which automatically decelerate when obstacles are detected within 2 meters and make an emergency stop within 1 meter;

-The hydraulic system is equipped with an overload protection valve, which automatically locks when the load exceeds the safety threshold to prevent equipment damage.

The design of the 80 ton dual hydraulic steering mold transfer railless vehicle always revolves around "precision and safety in heavy-duty scenarios". It is not only an efficient transportation equipment, but also embodies the wisdom of "demand as the core" in industrial design - using technology to break the contradiction between weight and flexibility, making heavy-duty transportation from "difficult" to "normal".

80 Tons Battery Powered Transporter Technical Parameters:

Load capacity: 80 tons

Table size:6*3*0.1m

Operate mode: remote control+ hand pendant

Protective device: alarm light, emergency stop button, laser scanning sensor

Speed: 0-25m/min

Brake:Electromagnetic brake

Power supply mode: maintenance free lead acid battery

Painting: Yellow+gray

Other customized functions: hydraulic lifting or Scissor fork lifting

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.